< Back to blog

CNC Plasma Cutter vs. Waterjet: A Comprehensive Comparison for Precision Cutting Services in Ireland

Contents

- Introduction

- The Power of CNC Plasma Cutters

- Unleashing the Potential of Waterjets

- Choosing the Right Solution for Your Business

- Conclusion

1. Introduction:

When it comes to precision cutting services in Ireland, businesses often encounter the choice between CNC plasma cutters and waterjets. Both options offer unique advantages, but understanding the differences and benefits of each technology is crucial for making an informed decision. In this blog post, we will delve into the comparison of CNC plasma cutters and waterjets, exploring their capabilities, applications, and performance. Whether you're in the manufacturing, construction, or metal fabrication industry, this guide will help you navigate through the decision-making process and select the ideal cutting solution for your business.

2. The Power of CNC Plasma Cutters:

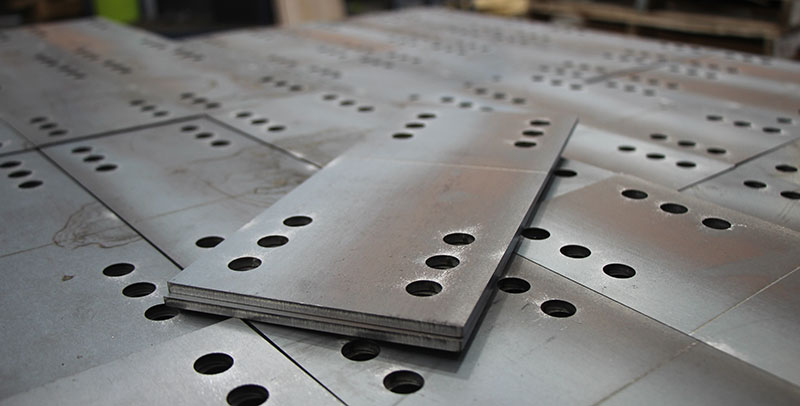

CNC plasma cutters have long been a staple in the metal cutting industry, offering efficient and precise cutting capabilities. Here are some key features and benefits of CNC plasma cutting:

- Speed and Efficiency: CNC plasma cutters excel in terms of speed, allowing for rapid cutting of various metals, including stainless steel, aluminium, and mild steel. This efficiency translates into reduced production times and increased productivity for your business.

- Versatility: With a CNC plasma cutter, you gain the ability to cut through different thicknesses of metal with ease. Whether you require intricate shapes or straight lines, plasma cutting technology can accommodate a wide range of cutting needs, delivering high-quality results consistently.

- Cost-Effectiveness: Plasma cutting is generally more cost-effective than waterjet cutting, especially for thicker materials. The lower initial investment, reduced maintenance costs, and efficient material utilization make CNC plasma cutters an appealing choice for businesses looking to optimize their budget without compromising on quality.

3. Unleashing the Potential of Waterjets:

Waterjet cutting technology has gained significant popularity in recent years due to its unique set of advantages. Let's explore why waterjets may be the ideal choice for your precision cutting requirements:

- Precision and Versatility: Waterjets are renowned for their exceptional precision, capable of delivering intricate cuts with minimal kerf width. This technology is particularly well-suited for projects that demand intricate designs, detailed shapes, and delicate materials like glass or stone.

- Material Compatibility: Unlike plasma cutters, waterjets can cut through a broader range of materials, including metals, plastics, composites, glass, and ceramics. This versatility allows for greater flexibility in handling diverse cutting projects, making waterjets an attractive option for businesses with varying material requirements.

- Heat and Environmental Impact: Waterjet cutting is a cold cutting process, meaning it generates minimal heat during operation. This attribute prevents material distortion and eliminates the risk of heat-affected zones (HAZ), particularly crucial for heat-sensitive materials. Additionally, waterjets are an environmentally friendly choice, as they do not produce hazardous fumes or release harmful by-products into the atmosphere.

4. Choosing the Right Solution for Your Business:

Selecting the most suitable cutting solution for your business requires careful consideration of your specific requirements. Here are a few factors to consider:

- Material Type and Thickness: Determine the primary materials you work with and their thickness. While CNC plasma cutters excel in cutting thicker metals efficiently, waterjets offer broader material compatibility.

- Precision and Complexity: Assess the intricacy and complexity of the designs and shapes you require. If you prioritize fine details and delicate cuts, waterjet technology may be your best bet.

- Budget Considerations: Evaluate your budget constraints and weigh the initial investment, maintenance costs, and material utilization efficiency associated with each technology.

5. Conclusion:

In the realm of precision cutting services, the choice between CNC plasma cutters and waterjets is ultimately dependent on your unique needs and requirements. Both technologies offer distinct advantages. If you prioritize speed, efficiency, and cost-effectiveness for cutting thicker metals, CNC plasma cutters are an excellent choice. On the other hand, if you require intricate designs, versatility across various materials, and minimal heat impact, waterjets may be the ideal solution for your business.

To make an informed decision, carefully evaluate factors such as material type and thickness, precision requirements, and budget considerations. It's also advisable to consult with industry experts or cutting service providers who can offer insights tailored to your specific needs.

At PlasmaCut.ie, we understand the importance of precision cutting services for businesses in Ireland. Our team of experts are equipped with state-of-the-art CNC plasma cutting technologies to cater to a wide range of cutting requirements. Contact us today to discuss your projects and explore the optimal cutting solution for your business.

Remember, whether you choose a CNC plasma cutter or a waterjet, investing in high-quality precision cutting services will ultimately enhance your productivity, expand your capabilities, and contribute to the success of your business.